FAQ

- Individual protection of each step by fuses or circuit breaker

- Fast ceramic discharge resistor integrated in each capacitor to avoid the risk of electrocution

- Environmental protection : no oil is used in our capacitors : biodegradable semi-dry resin

- Individual protection of each step against the phenomenon of harmonic resonance and overloads

- General protection against short-circuits by a magneto-thermal circuit breaker integrated in the capacitor bank (optional)

- Protection against overloads and overpressures by internal fuse in each capacitor

- Triple protection against overheating by external temperature sensor, internal measurement of temperatur by the PFC controller and temperature sensor in each detuned reactor

- Protection against overcompensation and under compensation thanks to the measurement of currents and voltages on the 3 phases simultaneously

- Protection against fire (optional)

- General residual current protection of the capacitor bank, to ensure safety against any ground current (optional).

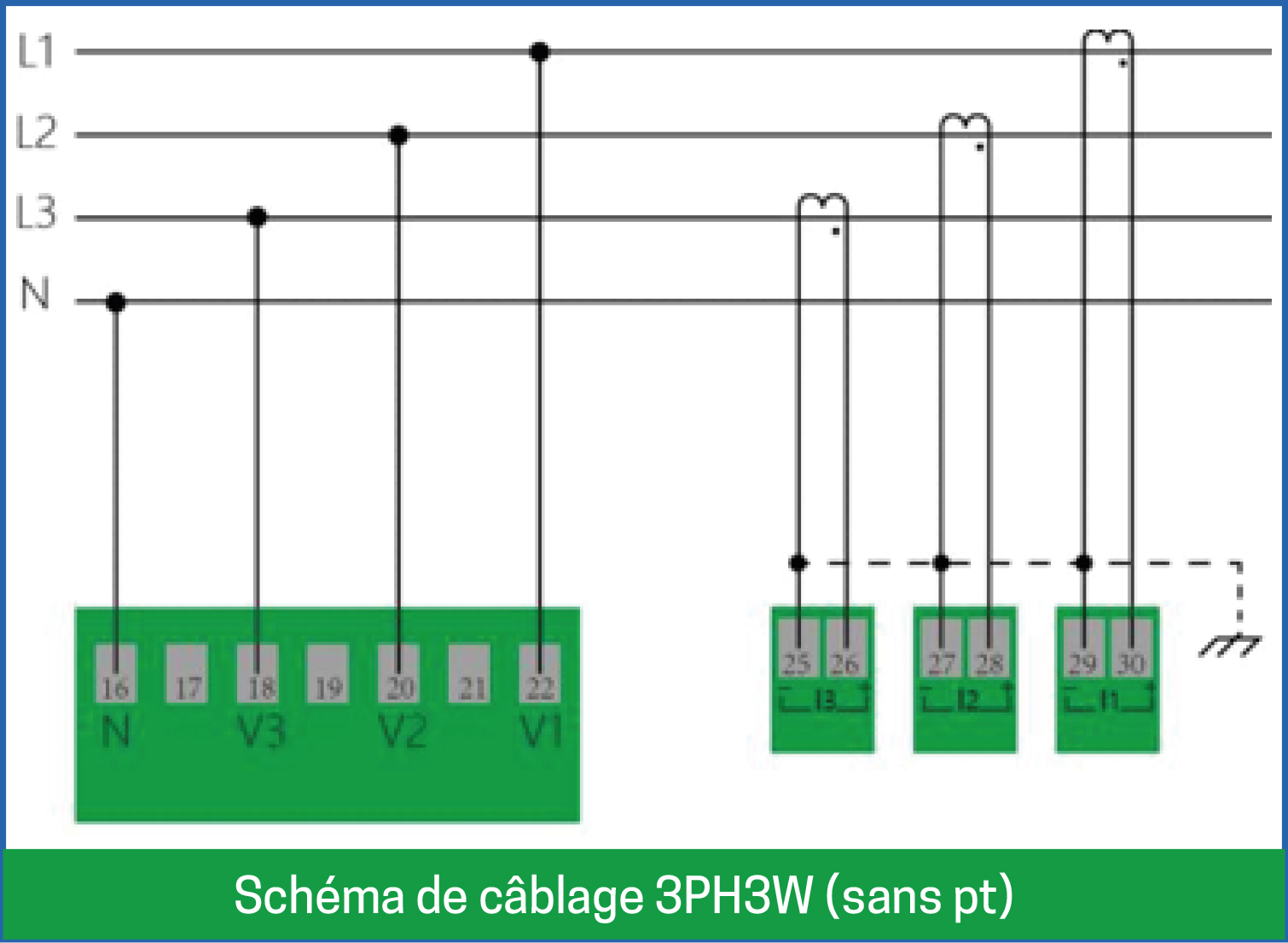

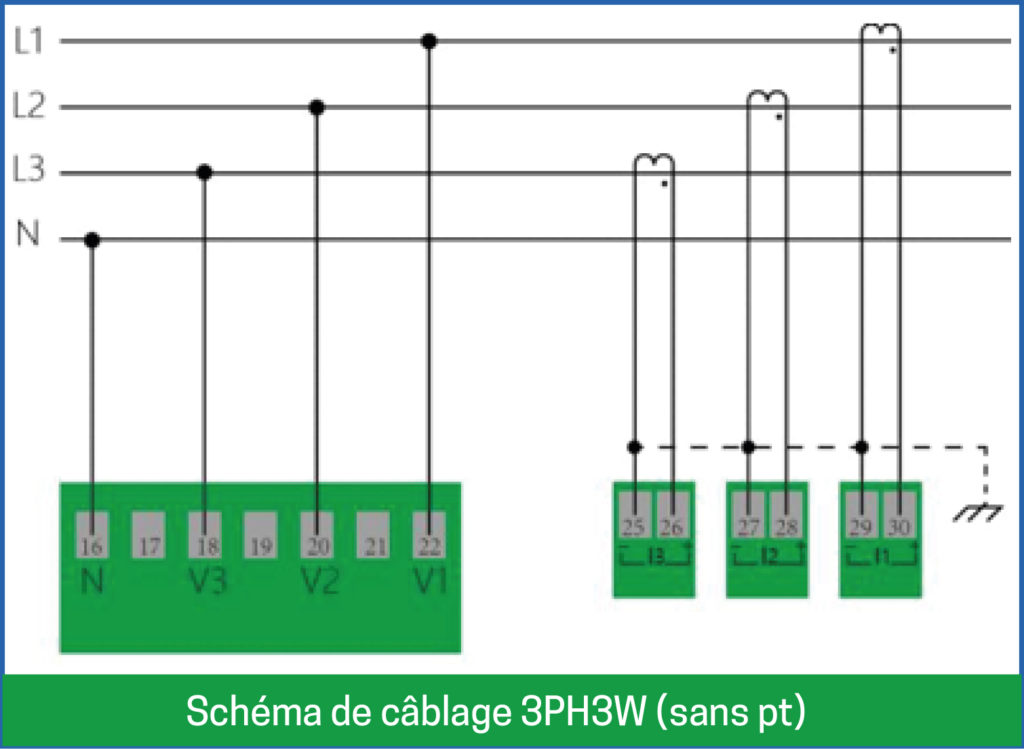

- Current and voltage measurement on the 3 phases

- Management of capacitor banks with single-phase, two-phase

- or three-phase reactors and capacitors.

- Load balancing function (management of single-phase,

- two-phase and/or three-phase steps)

- Capacitor Harmonics Load measurement (CHL) which permits

- to detect the resonance phenomenon

- Real-time measurement of the real power of each step (P and Q)

- Network analyzer function class 0.2s.

- Up to 3 external alarm outputs.

- 1 external input : allows to detect the switch to Genset or the

- activation of the emergency stop and to deactivate instantly all the steps

- USB port for programming and parameterization

- RS485 communication port (Modbus).

VARCap® series represents a new generation of power factor correction (PFC) capacitors based on the MKK AC technology from TDK®. This breaktgrough technology has brought the following innovations :

- Self-healing polypropylene film

- Pressure sensitive disconnector on 3 phases

- Biodegradable soft resin

- Pre-installed ceramic discharge resistors

- Finger protection terminals

- High thermal efficiency

- Vertical or horizontal installation

- High long-term stability.

Technical data :

- Voltage range 230 V … 1000 V

- Power range 5.0 kvar … 50 kvar

- Extended life expectancy up to 240,000 hours

- Supports a maximum current Imax = 2.0*Ir

- (including the combined effects of harmonics, overvoltages and capacitance tolerance the standard only requires 1.3*Ir)

- Supports inrush current up to 500*Ir

- Up to 15,000 operations per year

- Maximum operating temperature 60°C

- IP20 degree of protection

- Complies with IEC 60831-1 and -2 standards

10 compelling reasons to choose VARsys :

- 1

Range entirely tested and certified

- All the range has been tested in laboratory

- Certificate of conformity to IEC 61921 : 2017 and IEC 61439-1 : 2014

- 100% of the products are tested at full load in the factory before delivery

- 2

Design for easy preventive maintenance. All connections are visible on the front side.

- 3

Fire/overheating, Protection system

- 4

Optimal electrical protection

- 5

VARcap® cylindrical capacitors over-reinforced

- 6

4 levels of protection against overheating

- 7

Possibility to connect directly to the Normal/ Emergency busbar (Genset)

- 8

The most advanced intelligent PFC controller on the market Genius® A316

- 9

Optimized floor space

- 10

100% of the products tested before delivery

- Near the Connection Point of the Compensation Battery : Place the CT on the line that will supply the compensation battery. This allows for measuring the current flowing to the battery and accurately assessing its operation.

- Before the Connection Point of the Main Circuit Breaker : It is common to place the TC before the main circuit breaker to obtain an overall measurement of the current entering the compensation system. This allows for monitoring the total impact of the compensation battery on the installation.

The protection rating of the CMM72 network analyzer is IP64.

The entire CMM range is communicative.